NBS Source - a new future for manufacturer product information

30 March 2020

At NBS, our vision is to be the information platform for the construction industry. Our mission i...

29 August 2024 | By NBS

Get an inside perspective into how NBS software supports specifiers during projects and how manufacturers can better ensure they are seen, selected and specified.

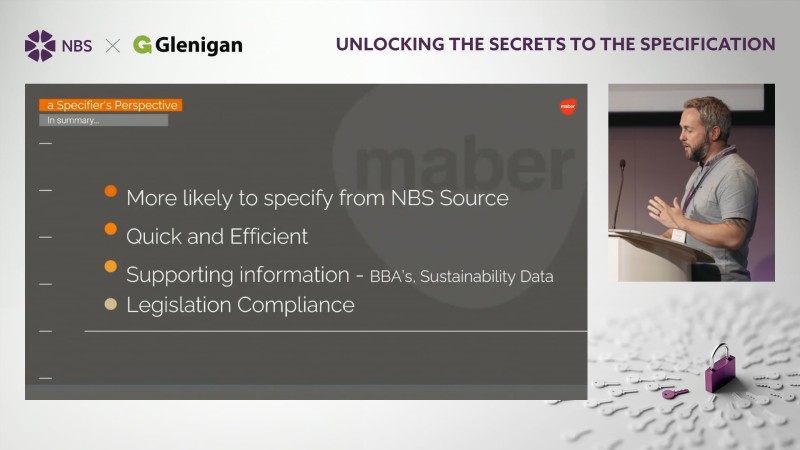

If you want your products to be found and specified, you need to know how architects approach the process. Nick Greenwood, an architectural designer at Maber, recently gave us an insider’s view into how he works with multi-disciplinary teams in a 3D environment to create projects – relying on NBS software to help identify appropriate products to be used within the spec.

As a construction manufacturer, knowing how an architect approaches the design process is crucial and Nick is an excellent source of information. Not only does he know a thing or two about specification as a whole, but he also played a pivotal role in shaping the NBS product ecosystem to support specifier’s needs.

He was on the advisory panel for the creation of NBS Create, the platform that eventually evolved into NBS Chorus that we use today. He also led on connecting the specification software and 3D modelling tools, bringing together two worlds that can work together to improve the whole architectural design process.

So what knowledge does Nick have to help you get your products in front of decision-makers to be chosen at the specification stage.

Specifiers are busy people. The project delivery process is one which requires significant plate spinning from the specifier. Nick explains: “We’ve got this central element of project delivery, but we also have all of the other elements that we’re juggling on a day-to-day basis.

“We deal with clients, and talking about fees and appointment documents, then we are utilising software, managing admin, talking to planning departments about bricks or cladding materials, and then bringing all of this together in the design and specification through team meetings and scheme options.”

If you can recognise the bustling workflow of a specifier, you can see how the NBS platform has become an essential tool. It helps alleviate many of the burdens encountered during the traditional specification process and enables users to work smarter and safer, collaborate better and connect their workflows across teams.

NBS Chorus is a cloud-based system, so specifiers can use it more flexibly to fit into their working lives. It supports collaboration between team members and manufacturers within the platform, which speeds up the entire process and creates streamlined ways of working.

Most importantly, the product data required from both specifiers and manufacturers within NBS Chorus ensures that all specifications produced within the system meet the strict safety requirements posed by the Building Safety Act. Additionally, other important product data-related issues such as planning consent and site inspections are contained in the same place.

“NBS Chorus is a collective point of reference for the project development as a whole.”

Simply put, the NBS platform has been designed and refined with the support of people like Nick to make sure it meets the needs of busy specifiers. Now, it is the go-to system for building specifications in the UK because architects feel confident that all aspects of their designs (including product selection) meet the necessary standards of their project.

Manufacturers who understand the specification process and the role NBS Chorus plays can capitalise on some key opportunities to get their products found and specified. Let’s refer back to Nick’s insights to get a closer look at how you can achieve exactly that…

To really tap into opportunities for manufacturers, we need to look at how a specifier uses NBS throughout a project’s lifecycle. Nick shared this information in the context of the RIBA Plan of Work. At each stage laid out by RIBA, specifiers can access information insight to inform the design process, from an initial brief all the way through to the development of the Building O&M Manual.

Chorus tracks all changes automatically throughout the RIBA stages, while all information is continuously checked and updated by NBS.

Here’s how a project timeline typically works for a specifier:

Taking the initial briefing information, a specifier can drop in the materials required, such as brick or other masonry. This can be simplistic at first, with additional detail added at a later stage. Doing this so early on benefits the specifier greatly, as they can build up a picture of the materials required.

For manufacturers, the early stages of a specification are descriptive and based on a client briefing – so an architect isn’t likely to select your specific insulation system…yet.

However, specifiers often still choose products or systems at this stage based on broad criteria such as wall thickness or energy efficiency. If your product is listed via NBS Source and your data matches their broader search requirements, you may find your system is used even at this early stage.

Being included in a specification this early is a good opportunity to start a dialogue with the specifier through NBS Chorus and support them further. You may even be able to collaborate on the spec itself. By building your relationship and supporting a specifier’s needs, you decrease the risk of having products swapped out.

Once a project moves into these stages, architects will have tested the design against the client’s spatial requirements and have a far better idea of the exact requirements they have for materials and systems from a performance and cost point of view.

Chorus allows them to find products which meet their exact specifications. This stage is also critical for project submissions, so being able to provide designs with material specifications will further improve the quality of any necessary submissions.

By the time Stage 4 ends, specifications are fully prescriptive – every product/system is described in detail so that it is ready to be built. If your product isn’t used in a specification by Stage 4, you’ve likely missed your opportunity.

Manufacturers who take the time to include a rich level of technical product data in all of their products are the ones who will be found and selected at this stage. If your products aren’t listed on the NBS platform and don’t have the right information accompanying them, a specifier won’t be able to confidently add it to their specification.

All pieces of the puzzle start to come together here, and Chorus allows specifiers to dig into the details and finalise systems with the execution and completion causes in line with Building Safety regulations, and any other requirements set out by Planning Authorities, etc.

Stage 5 is all about ensuring you’ve provided the right level of data to a specifier. Installation guidelines, for example, must be accessible to the specifier so they can be included in the final spec document.

The production of a final specification with a detailed outline of all aspects of the building, covering everything from the construction to facilities and maintenance.

With a need for up-to-date information in every specification, the value of NBS Chorus becomes even clearer. Not only will a specification produced via NBS Chorus automatically update and record all changes based on the specifier’s actions – but NBS also prompts manufacturers to update your product data whenever required. This means architects and, post-handover, the building owners, always have access to your most recent data, including safety certificates and maintenance manuals.

Throughout the process, NBS Chorus is updating and recording changes across the entire project, giving specifiers the confidence that all specification choices are in line with any guidances and necessary legislation as the project progresses.

After looking at a specifier’s process and how NBS Chorus is used at every stage, you can see how important it is for manufacturers to ensure their products are accessible on Chorus.

Nick confirms this notion in the presentation: “NBS Chorus provides a safety net in terms of the construction element onsite. It allows us to speed up my production information, and ensure efficiency. So, when I am writing a specification, I can look to NBS for a product that I can specify, and I can start to build up that information.”

If you don’t list your products, they may never be found. Specifiers sometimes encounter this exact scenario if they search for a product that should be available, but a manufacturer hasn’t uploaded it to NBS Source. Nick explained how frustrating the ‘no products found’ result is for specifiers who are trying to speed up their workflows:

“When no products are available, my heart really does sink. I then have to go and find the manufacturer myself, and this is slow, ineffective, and frustrating at times.”

Like Nick says, this gap in the product availability is a problem for specifiers, as it means they have to dig around looking for products that may fit their requirements using search engines and external websites. They then they need to cross-reference with building safety regulations, and ensure it can work with other specifications listed in their system.

The whole process is an arduous one, but it can be easily solved by manufacturers who embrace Chorus and actively embrace the platform for connecting their products to specifiers like Nick.

“It shows me that manufacturers want their products to be specified. I know that when I see all of those products the supporting information is there. Therefore I’m much more likely, wanting to be quick and efficient about my specification, to use the products that are available.”

For specifiers, it’s all about speed and efficiency without sacrificing accuracy or quality, and having manufacturer products available on NBS Chorus is the key to succeeding in this mission.

Now we know how it works in theory, let’s take a closer look at a project that Nick is working on, and how Chorus has allowed him to efficiently drop in products to the specification.

A timber-framed building in Lincolnshire has a boundary condition, and also requires additional fire resistance. Nick uses NBS to find a fire-rated sheathing board to ensure the scheme meets the fire resistance requirements across the wall.

Through the search on NBS Source, Nick found a Klasse G-board Gypsum External Sheathing Board that already has BBA certificates, as well as technical data, so he can reassure any stakeholders or authorities that the product in question is fit-for-purpose and meets any necessary requirements.

In NBS Source, specifiers have all supporting information for products at their fingertips, making it easier to provide everything they need to ensure compliance with necessary building legislation, which is only getting more prevalent for those development systems.

Architects are more likely to specify from NBS Source, as it makes a complex process more accessible, and ensures accuracy and compliance at the same time. So, how can manufacturers improve their chances of being selected by specifiers? Here are some tips:

We know that architects are saving time and resource by embracing digital technologies in all areas of their work. This isn’t just about specification, but also with regards to BIM models and other digital resources. By using NBS’s platforms, manufacturers can ensure their products align with the UK BIM Framework using Uniclass and CAWS.

The NBS platform gives manufacturers valuable insight into specifier needs. You can see if your products are being considered for a project and can easily reach out to specifiers to resolve queries or offer collaboration. This not only provides actionable information to manufacturers, but it also gives you a higher chance of being selected for the final development.

NBS requires manufacturers to meet high data standards by providing comprehensive information alongside each product, giving specifiers everything they need to ensure each specification meets the Buildings Safety Act and any other compliance requirements.

So, as a manufacturer, the more information you can provide, the more likely a specifier is to select your product for their spec and, ultimately, for the final development, as they are confident that the product you can provide will meet their needs and comply with industry standards.

Through NBS Chorus, manufacturers can collaborate with specifiers to provide support and guidance in their areas of expertise. Architects can then use this specification or adjust it accordingly, giving them a foundation for how best to use your product in their system.

So, by taking advantage of all NBS has to offer, manufacturers can better benefit from the platform and increase the prevalence of their products by specifiers.