Building Safety: The Time To Act Is Now

13 February 2024

Recap Dame Judith Hackitt’s excellent speech on upcoming changes to the Building Safety Act and w...

31 May 2017 | By Dr Stephen Hamil

As a construction product manufacturer, what should be at the heart of your digital strategy?

The construction industry has changed for manufacturers: it was not so long ago that manufacturers would distribute stencils for architects to draw drawing details. Until recently at NBS, we posted hard copy RIBA Product Selector product directories to thousands of offices in the UK. Additionally, we had an office library service which involved going into organisations’ office libraries to place the latest manufacturer literature on the correct shelves.

The digital revolution has changed all of this. Construction professionals demand efficiencies and the most up-to-date information so that they can make the correct decisions quickly and minimise risks on projects.

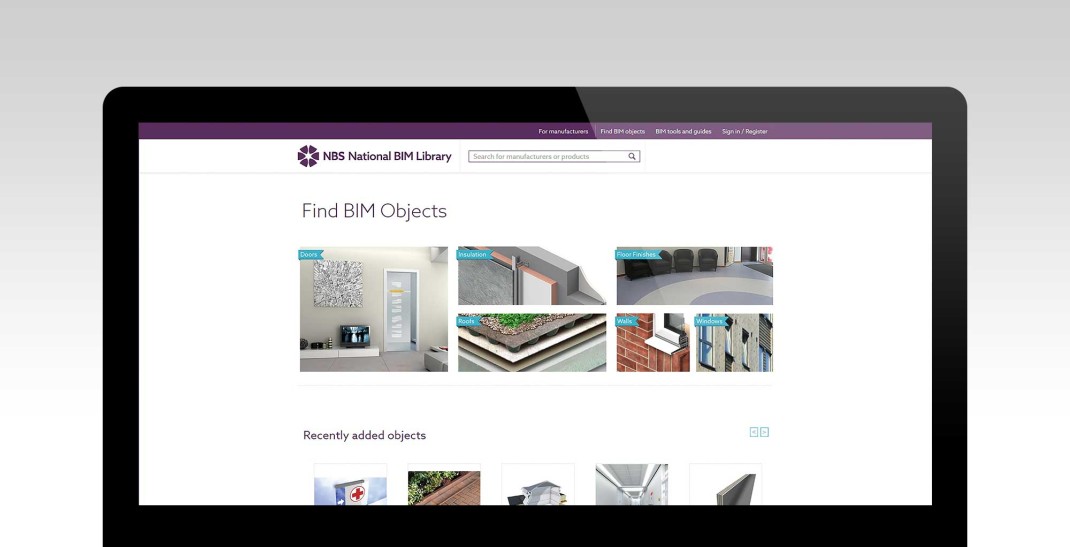

With respect to digital information and the construction industry, the recent focus has been on BIM objects and data templates. We like to think that NBS has been one of the leaders here. We now make tens of thousands of standardised objects from over 300 manufacturers freely available, from radiators to cubicles to roof constructions. However, it’s not just the volume of content that makes NBS different, but also our recognition from the start that the industry required a standardised approach to BIM object creation. This is why we developed the NBS BIM Object Standard and associated guidance. We then provided this to the industry for free, so that any organisation authoring BIM objects can do so to the same standard. This BIM Object Standard demands the use of standardised international IFC and COBie classes and properties, and helps enforce the requirements of the UK’s BS 8541 modelling standards.

With respect to the information that is specific to a system or product type, as part of the UK BIM Task Group-commissioned BIM Toolkit project, we delivered data templates for around 6,000 systems and products. These property sets and associated guidance have been authored and are maintained by NBS technical authors. We do recognise that there is more to be done here and that these templates need further depth. We are working closely with industry groups such as the European CEN 442 committee and buildingSMART International to achieve this.

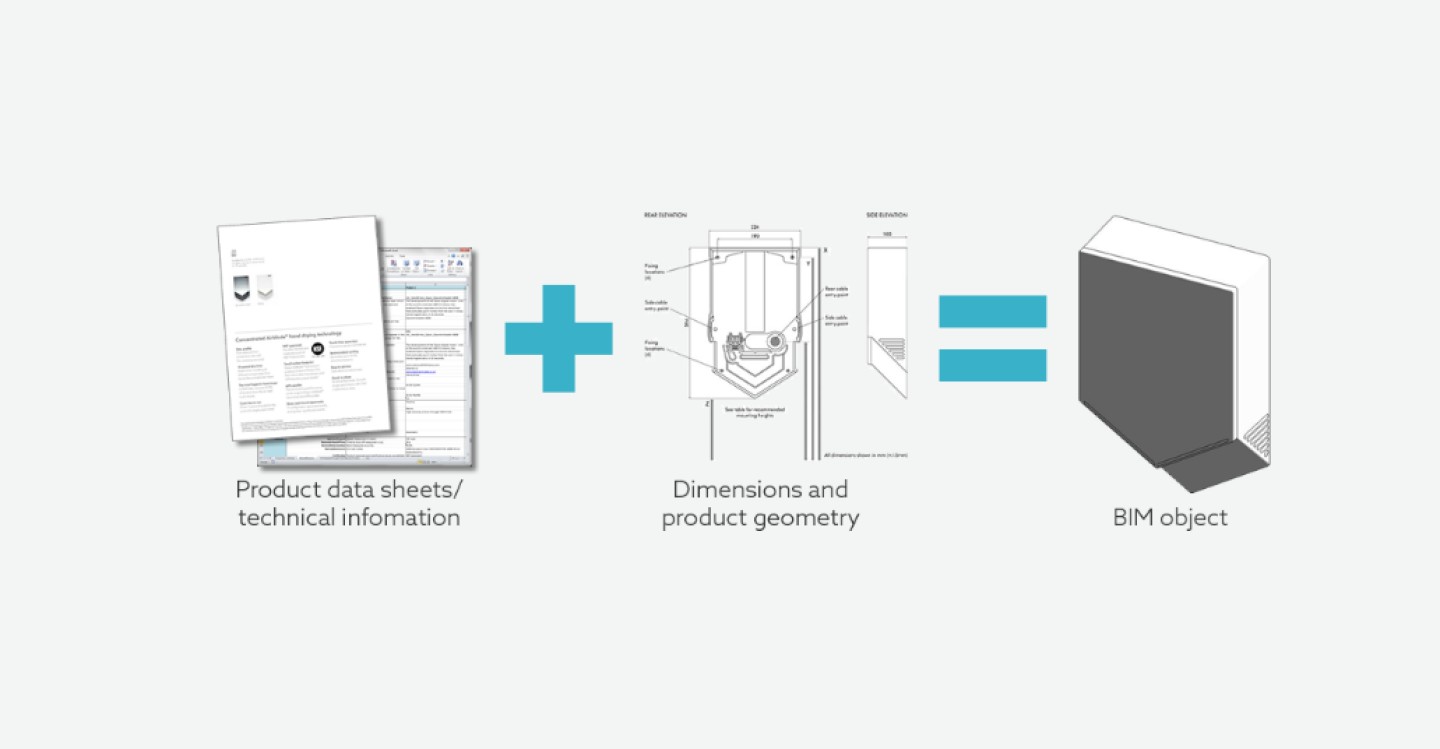

We also recognise that there are workflows that do not require geometrical information, and in certain situations, property values and the associated guidance about manufacturer products is all that is required. We have been delivering one of these workflows to UK construction professionals for many years now.

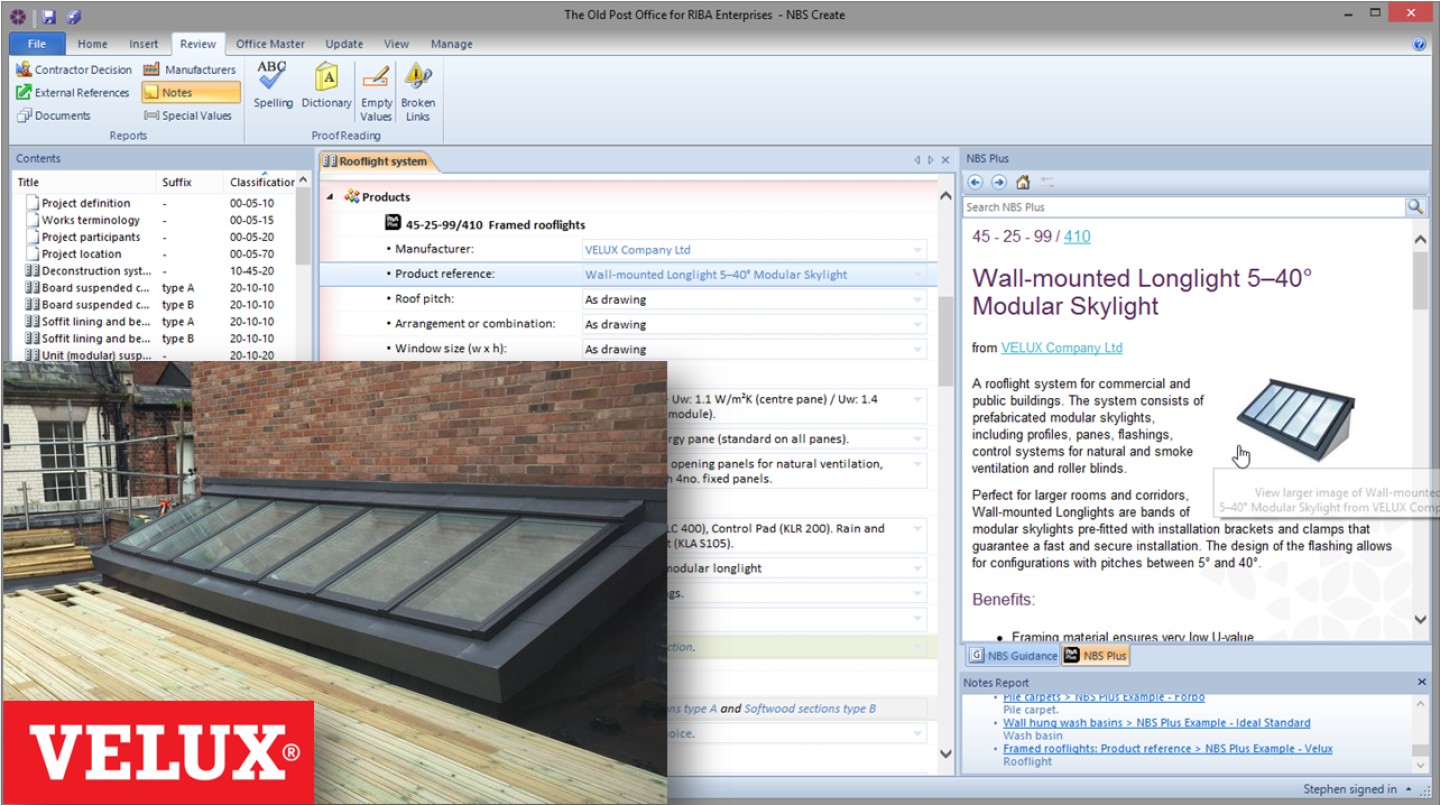

All of our specification products, from NBS Scheduler to NBS Building to NBS Create, contain the NBS Plus service. This delivers manufacturers’ technical information from the cloud directly into the user’s specification. This is the de-facto method of specifying in the UK, and over 600 manufacturers have their products in this service. With respect to the delivery of manufacturers’ well-structured digital information, it must be recognised that at different points of the project timeline different information is required. When designing, the architect or engineer may require a 3D BIM object that they can drag and drop into their model. When specifying a product to meet a particular performance requirement then, a cut of the appropriate data is needed.

When running focus groups with manufacturers over recent years, one common theme always emerges. This theme is that it isn’t just about the information: product selection, design and specification cannot be commoditised. It is not just about the fire rating or the durability of the product; it is also about the service that the manufacturer offers, and it is also about the associated information that will exist in PDF format for many years to come.

Most manufacturers will offer free technical advice. Many manufacturers offer a design and specification service. Specifiers will want assurances about the support that will be offered to their clients when the system or product has been installed within the built asset.

It is important that manufacturers promote the added-value services they offer on their websites and link to them from within their structured technical information. Examples of evidence of the quality of the offering include linked third party approval certification, case studies and testimonials, design services, the provision of CPD and the availability of operation and maintenance literature.

The majority of manufacturers in the UK have started their digital transition. The days of printing thousands and thousands of catalogues are becoming the past. The information from these catalogues now exists in BIM objects; linked, well-structured data; and online PDFs and web applications.

The final consideration for a manufacturer is how best to place this information in their customers’ (and their potential customers’) workflows. As a parallel example, an estate agent invests in their own website and database, but they also make sure that their content is pushed into the main channels, such as Rightmove, which the market is using to make decisions.

Similarly, the construction manufacturer needs to make their well-structured data available on the websites that the industry is using for product selection and discovery. They must place their product information inside widgets in the leading design and specification products so that their BIM objects and specifications can be added to a project in a single click.

The industry has changed: it is now digital. If you are a manufacturer contemplating your digital strategy, then consider the following three items as part of this: