Making Specification Safer: The BBA and NBS

24 March 2025

See how a partnership between the BBA, RIBA & NBS helps heighten safety standards from the earlie...

03 May 2024 | By NBS

Digital tools have transformed the specification process. Manufacturers who can understand and adapt to these changes can win more work at the specification stage and improve sales.

Digital tools have transformed the specification process. Manufacturers who can understand and adapt to these changes can win more work at the specification stage and improve sales.

The construction industry continues to adapt to a digital revolution, with new technologies and processes constantly cropping up and causing widespread change.

Innovations in technology, combined with government-backed support for concepts such as building information modelling (BIM) and the golden thread of information, mean that everyone working in construction must embrace digital technology in order to stay ahead of the curve.

One of the areas most impacted by the digital revolution is the specification cycle. Not only do architects now have efficient digital tools to help them plan projects, but they also enjoy an unrivalled level of freedom when it comes to accessing product information and incorporating suitable products into specifications.

As a construction manufacturer, understanding how specification has changed and its importance in the industry will help you get your products in front of more decision-makers and, ultimately, sell more products.

When we talk about specification, what does that actually mean in the context of construction manufacturers? If you’re wondering how it relates to you, here’s an official definition:

"Specification: A detailed description of the dimensions, construction, workmanship, materials etc., of work done or to be done, prepared by an architect, engineer etc."

- Shorter Oxford English Dictionary

Essentially, a specification is a document that details the ‘plan’ for a project, including the materials, dimensions, workmanship standards, etc. It establishes what cannot be visualised or explained on a drawing or model – though it may also provide additional context to existing drawings or plans. Specifications apply not only to construction; the same principles apply to all industries, from aerospace and oil and gas to automobiles and manufacturing.

In construction, however, the specification covers topics such as:

● Site establishment.

● Contract type.

● Asset performance criteria.

● Systems and product quality.

● Applicable standards and how they are executed.

● Specific products to be used.

The type of specification can relate to the project or the procurement route – whether it is performance-based, prescriptive or proprietary – depending on project requirements.

To summarise, specifications:

● Are required during the design stage.

● Form part of the contract documentation.

● Play a key role in project fulfilment.

While it might be architects who produce specifications, manufacturers need to understand the process and recognise the value of specifications in order to get ahead of their competitors and improve their sales.

Specifications used to be one of the last items written before issuing a tender package; however, this has changed over time, especially since the advent of BIM.

Nowadays, the best practice is to begin specification writing as early as possible in the project lifecycle. Early-stage specifications can capture information from the client review, documenting what the client is trying to achieve on the project.

Early-stage work also provides a better understanding of a project's performance requirements. Any information incorporated into the client's EIR (employer information requirements) and discussions on complexes, entities, spaces, locations, elements, systems, and products contribute to the specification as it builds.

As a manufacturer, opening dialogue with architects at an early stage allows you to collaborate on specifications and ensure your product is included. Once specified, you have a far higher chance of your products being implemented in the project.

NBS is the number one specification writing tool in the UK, offering architects around the world dedicated support for authoring industry-leading specifications. Over 98% of the AJ Top 100 Architects write specifications with NBS.

We work with these architects to author their content to the highest quality, ensuring full compliance with UK regulations and continually raising the bar when it comes to standards in the construction industry.

As a manufacturer, work with the NBS to become part of this process. By utilising NBS software, you can promote your products to architects during the specification process and even collaborate with them directly to improve the quality of the final spec.

By working through NBS, you’ll have access to a deep pool of the UK’s best architects who actively interact with manufacturers when writing specifications. Additionally, you’ll have the support of our team when it comes to creating and uploading your product data, BIM models and more.

The team at NBS has been developing and delivering specification products and tools for over 50 years, and we are continuously reviewing our content to reflect industry changes.

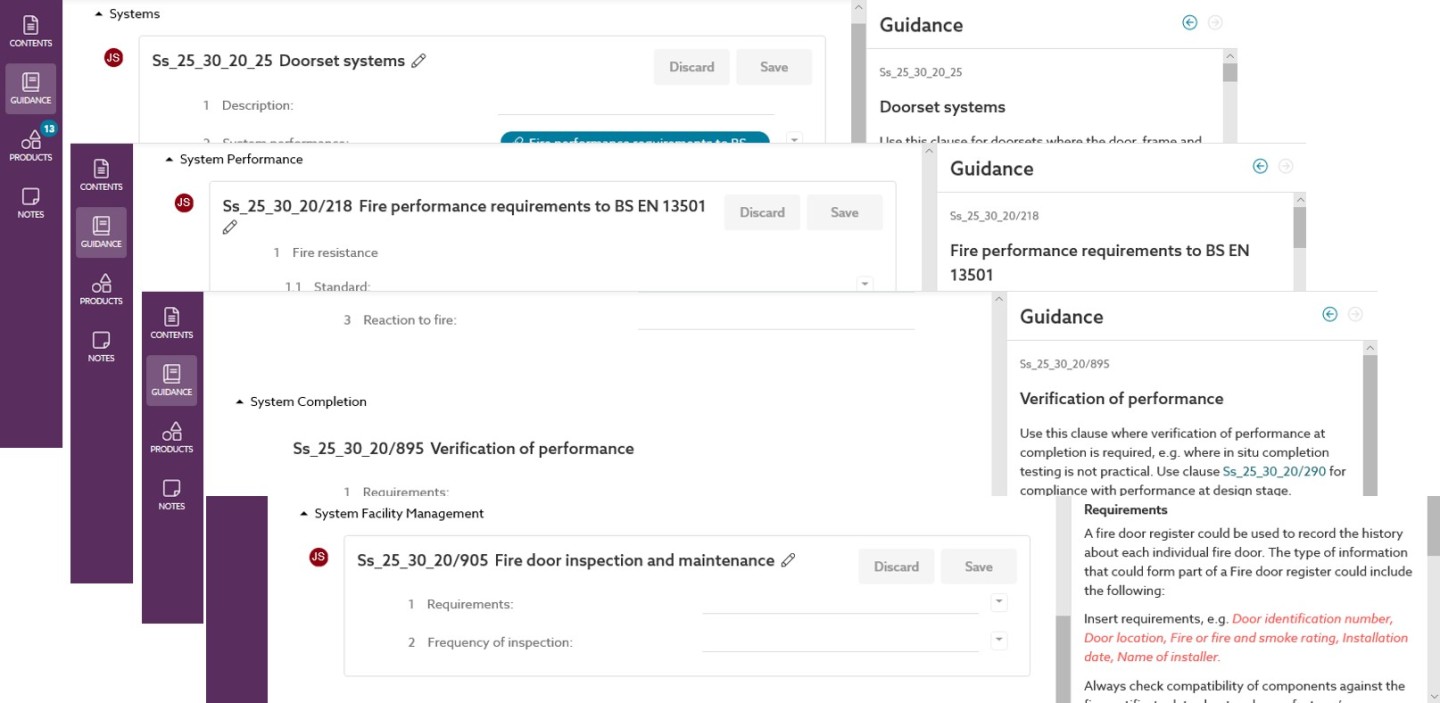

With cloud-based NBS Chorus, our users can write and deliver construction specifications in a BIM environment. For manufacturers, we have developed NBS Source. This building product library allows specifers to search easily for their products and unique to NBS, will serve relevant product options to specifiers a the right time from within the specification environment.